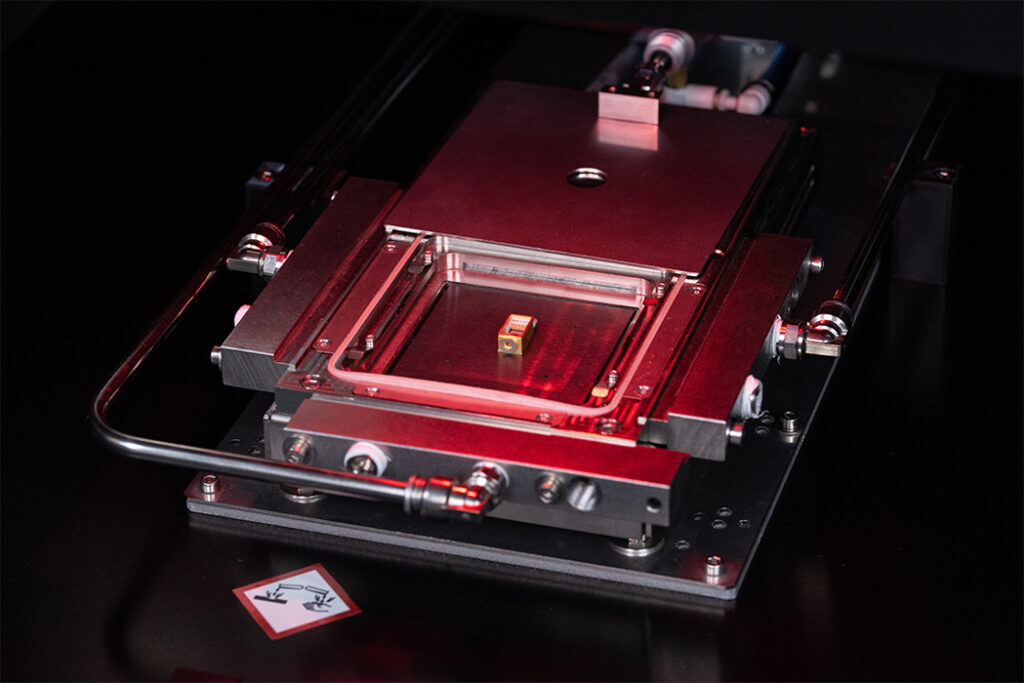

“The use of formic acid as a reducing agent generates oxide-free and well-wettable surfaces. This way ideal conditions for demanding soldering processes are created,” says Daniel Schultze, Managing Director of Tresky GmbH, introducing the formic acid module. Since solder processes in optoelectronics often cannot use conventional fluxes, Tresky’s R&D team has developed the formic acid module. The module is used in eutectic soldering and thermocompression bonding, for example with gold tin or indium. In all bonding processes, nitrogen is enriched with formic acid (HCOOH) through a so-called bubbler. The nitrogen-formic acid vapor mixture is introduced into the process chamber and vacuumed off in a well-controlled manner. “The control of this process is particularly important, because besides the best possible effect of the formic acid, the protection of the operator is also important,” emphasizes Schultze.

In optoelectronics and photonics, the requirements for packaging technologies, regarding voids or external impurities, are particularly strict. Formic acid offers reliable reduction of oxides with complete avoidance of flux. “Nitrogen enriched with formic acid is a stable, long-standing industry-proven and economical process in soldering technology for reducing oxide layers. Integration in our DIE bonders also enables our customers to create complex setups in optoelectronics,” Schultze continues.