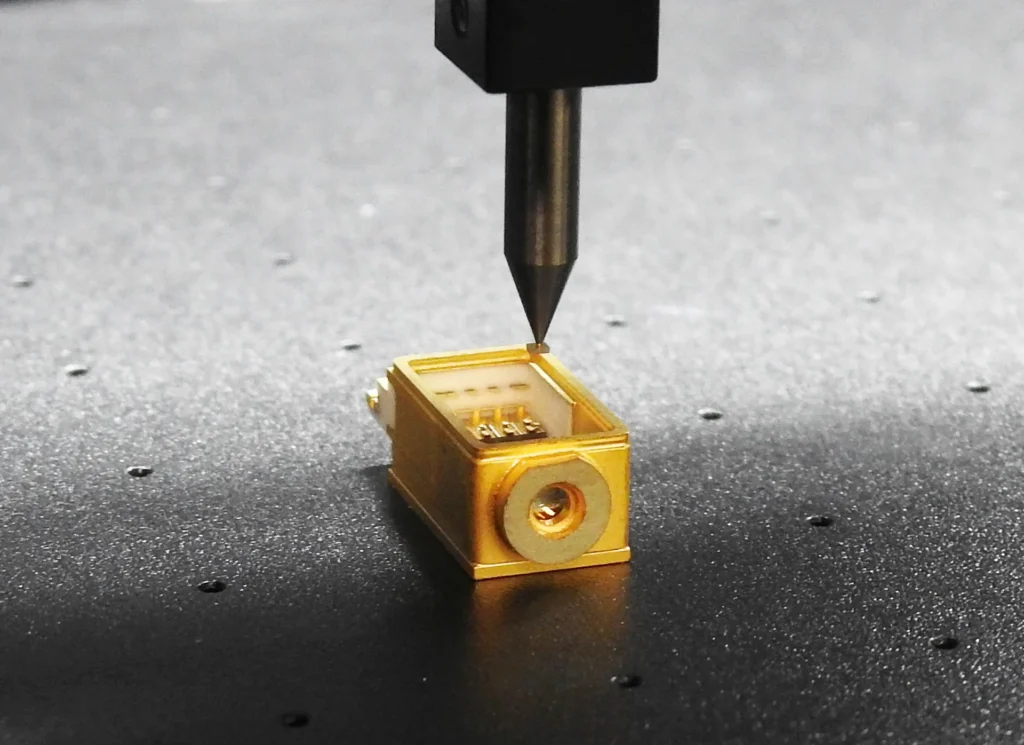

Optoelectronic components are used in a wide range of applications, from telecommunications to medical technology and industrial automation. The quality and reliability of these diodes depend to a large extent on the DIE bonding technology used. DIE bonding, also known as die attach, refers to the process by which DIEs (semiconductor chips) are bonded to a carrier substrate.

“This connection is essential to ensure the functionality of devices such as laser diodes, photodetectors, VCSELs and other optoelectronic components.”

Daniel Schultze, Managing Director of Tresky GmbH

Laser- and photodiodes are highly sensitive optoelectronic components that require precise placement and connection to their carrier substrates. With DIE bonding, the diodes can be mounted stable and highly precise on the substrate. Since a faulty connection can lead to power loss, signal distortion and inefficient light emission, the quality of the DIE bonding is crucial for the overall performance of the diodes.

“The use of advanced DIE bonding technologies is therefore essential.”

Daniel Schultze

Laser diodes generate significant heat during operation. This heat must be efficiently dissipated to prevent overheating and the damage that can result. DIE bonding therefore plays an important role in thermal management, as it ensures effective heat transfer between the diode and the substrate as a result of good bonding. Good thermal contact extends the lifespan of the diodes and improves their reliability. The mechanical stability of the connection is also essential for the long-term functionality of laser- and photodiodes. Vibrations, temperature fluctuations and other environmental influences can damage the diodes if the DIE bonding is not sufficiently stable. High-quality eutectic connections ensure that the diodes function reliably even under extreme conditions.

In advanced applications, laser- and photodiodes are often part of complex optoelectronic systems. Tresky’s DIE bonders enable the integration of these diodes into modules that perform multiple functions, such as signal processing and light emission.

“Precise DIE bonding is crucial to ensuring the interoperability and efficiency of these systems,”

”Our DIE bonders support various DIE bonding technologies, including eutectic bonding, epoxy bonding, UV bonding, ultrasonic bonding and more. This flexibility allows our customers to choose the method best suited to their specific applications.”

Daniel Schultze

Tresky continuously invests in research and development. The aim is to further optimize the technologies developed in-house and to bring innovative solutions to the market. Progress in DIE bonding makes it possible to open up new applications and push the boundaries of photonics.

“Our goal is to stay at the forefront of these developments. We want to offer our customers innovative products and solutions that meet the increasing demands.”

Daniel Schultze

As a leading manufacturer of DIE bonding systems, Tresky is proud to make a significant contribution to the DIE bonding of laser- and photodiodes in photonics.

“Our innovative solutions ensure the quality and reliability of these critical components and help our customers take their products to the next level.”

Daniel Schultze