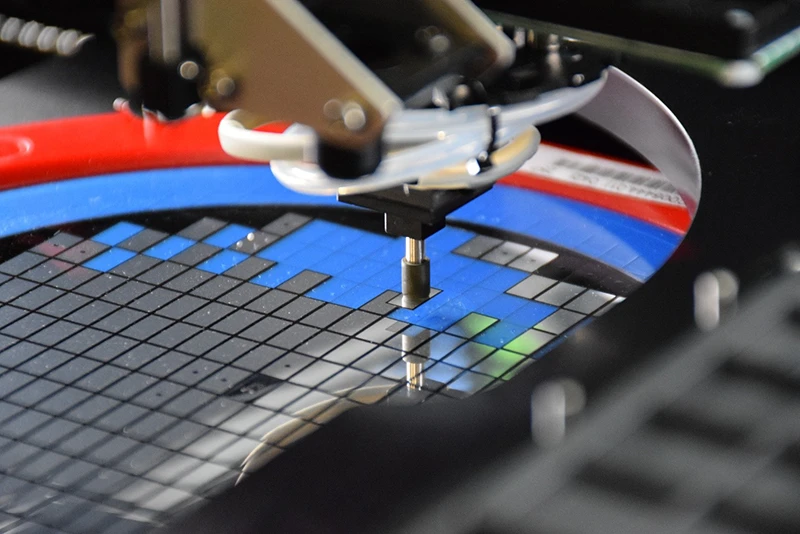

As a leading company in semiconductor technology, Tresky emphasizes the importance of the DIE sorting process. In this process, semiconductor chips (DIEs) are sorted according to various criteria such as quality, size, electrical properties and specific applications. This ensures that only flawless and efficient components are sent for further processing.

“DIE sorting is an indispensable service as soon as the highest standards in semiconductor production are to be guaranteed. But the subsequent secure packaging of the sorted DIEs is also crucial for a high quality standard,” explains Daniel Schultze, Managing Director of Tresky GmbH. Schultze, a proven specialist in DIE bonding, has extensive experience in dealing with sensitive semiconductors. To maximize the quality and efficiency of DIE sorting, Tresky uses its own systems to perform this process on behalf of its customers.

“Packaging semiconductor DIEs in gel packs, waffle packs, trays or tapes is essential for protecting these sensitive components during handling and transportation,” continues Schultze. Each packaging method offers unique advantages in terms of security, protection against damage, automation compatibility and storage efficiency. For example, gel packs are known for their effective cushioning properties, waffle packs are ideal for automated handling, trays allow for organized storage and tape & reel packaging is ideal for transporting large quantities of non-sensitive components.

“It is important to choose the right packaging method based on the specific requirements of the semiconductor components to ensure their safety and protection. Incorrect packaging can lead to damage that not only affects the quality of the DIEs, but also jeopardizes the entire production chain,” emphasizes Schultze.

Tresky GmbH works closely with its customers to develop customized solutions that meet their individual needs and requirements. “Our goal is not only to ensure the quality of the semiconductor products, but also to maximize efficiency throughout the entire supply chain,” adds Schultze.

By using the latest technologies and processes, Tresky ensures that the DIE sorting of semiconductors runs smoothly and reliably. This helps to strengthen the competitiveness of customers in an increasingly demanding market. “Customers who purchase DIE sorting from us benefit from numerous advantages,” explains Schultze. “Our precise sorting process ensures that only the highest quality DIEs are sent for further processing. This leads to a higher number of defect-free semiconductors, which increases the efficiency of the entire production.”

In addition, Tresky’s services help reduce production costs. By servicing the sorting and inspection of DIEs, companies can use their internal resources more efficiently and avoid the need for expensive investments in in-house sorting capacity. This allows customers to focus on their core competence while reducing operating costs. Another benefit is higher product quality. By carefully selecting and sorting the DIEs, companies can ensure that their end products meet the highest standards. This is especially important in industries where reliability and performance are critical, such as automotive, defense or medical technology.

In addition, this services optimize the subsequent production processes. By providing DIEs that have already been sorted and tested, companies can make their production lines more efficient, resulting in faster production and a reduced time to market. This is a crucial competitive advantage in a dynamic market where time is often equal to money.

“In summary, our DIE sorting service not only increases efficiency and quality, but also offers strategic flexibility to companies operating in a constantly changing environment,” concludes Schultze. “We are proud to be able to offer our customers these comprehensive benefits and support them on their way to success.”