Precision Technology for Nano- and Optoelectronics

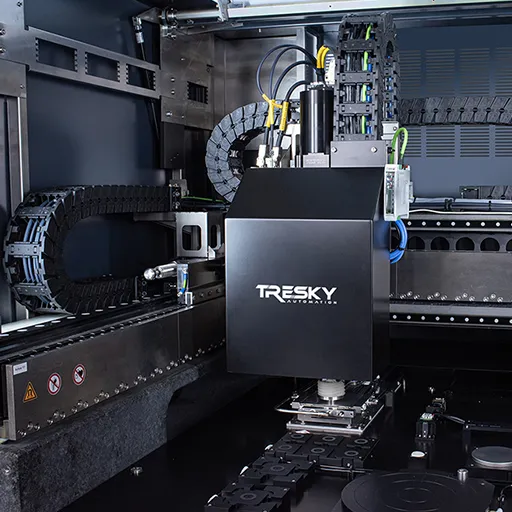

The photonics bonder is based on the T-7000 machine platform and is one of the most precise placement systems on the market due to its solid granite chassis. This precision is essential for use in the nanoelectronics and optoelectronics sectors.

New Standards in Precision and Flexibility

Technological miniaturisation and functional integration in nano- and optoelectronics are crucial for future-oriented product innovations. The high demands on the positioning accuracy and reproducibility of complex microsystems are a prerequisite for the quality and reliability of these products in the manufacturing and assembly process.

Flyer

Photonics Bonder

Laser- and photodiodes are highly sensitive optoelectronic components that require precise placement and connection to their carrier substrates. Our DIE bonding solutions allow the diodes to be mounted stably and with high precision on the substrate. Since a faulty connection can lead to power loss, signal distortion and inefficient light emission, the quality of the DIE bonding is essential for the overall performance of the diodes. The use of advanced DIE bonding technologies is therefore indispensable.

We have developed the photonics bonder to successfully implement these requirements. The bonder offers sub-micron placement accuracy, a travel range of 500 x 700 mm and a bond head with minimal bond forces. Optionally, the bond force range can be increased on customer request. Standard for us, the machine chassis is made of granite. This allows us to guarantee the highest possible precision for optical components such as VCSEL, laser, photodiodes, IR sensors or for the development of quantum technologies.

Furthermore, heat management plays an important role, since laser diodes generate a considerable amount of heat during operation. This heat must be efficiently dissipated to prevent overheating and the damage that can result. DIE bonding also plays an important role in thermal management since it ensures effective heat transfer between the diode and the substrate through good contact. A good thermal connection extends the life of the diodes and improves their reliability. The mechanical stability of the connection is also essential for the long-term functionality of laser- and photodiodes. Vibrations, temperature fluctuations and other environmental influences can damage the diodes if the DIE bonding is not sufficiently stable. High-quality eutectic connections ensure the reliable function of diodes even under extreme conditions.

In advanced applications, laser- and photodiodes are often part of complex optoelectronic systems. Our DIE bonders allow these diodes to be integrated into modules that fulfil multiple functions, such as signal processing and light emission. Accurate DIE bonding is critical to ensuring the interoperability and efficiency of these systems. Our DIE bonders support various DIE bonding technologies, including eutectic bonding, epoxy bonding, UV bonding, ultrasonic bonding and more. This flexibility allows our customers to choose the most suitable method for their specific applications.

Added Value

High Precision

Due to the granite machine platform, the photonics bonder is a high-precision placement system.

Versatility

All processes of the assembly and connection technologies offered by Tresky can be integrated. E.g. eutectic soldering or UV bonding.

Modularity

The photonics bonder can be customized to meet specific customer requirements and expanded with different options. This means that the bonder can be used reliably in prototyping, product development and series production of nano- and optoelectronics.

Time to Market

The prototype-to-production approach enables the photonics bonder to be used both in manual prototype production and in series production.

Bonding Forces

Optional high bonding forces also allow the photonics bonder to be used for hybrid bonding or high-precision sintering applications.

Variable Parameters for Photonics Bonding

- Bonding force (pressure)

- Temperature

- Bonding time